Wireline Products

The future is electric, digital and automated

Stimline manufactures automated, electrically driven wireline winches for the most demanding offshore operations. Whether you are into cased hole or open hole work our wireline units can handle the challenge.

By marrying the wireline units with the other ingredients of Stimline’s eco-system, the rig site unit can be closely integrated with digital workflows, to receive and automatically execute pre-planned conveyance jobs in and out of the wellbore, be safely operated from remote locations, and form part of a strategy for future autonomous operations, supported by advanced data science applications.

With Stimline your wireline units are prepared for the future.

Want all the Details?

Explore Products

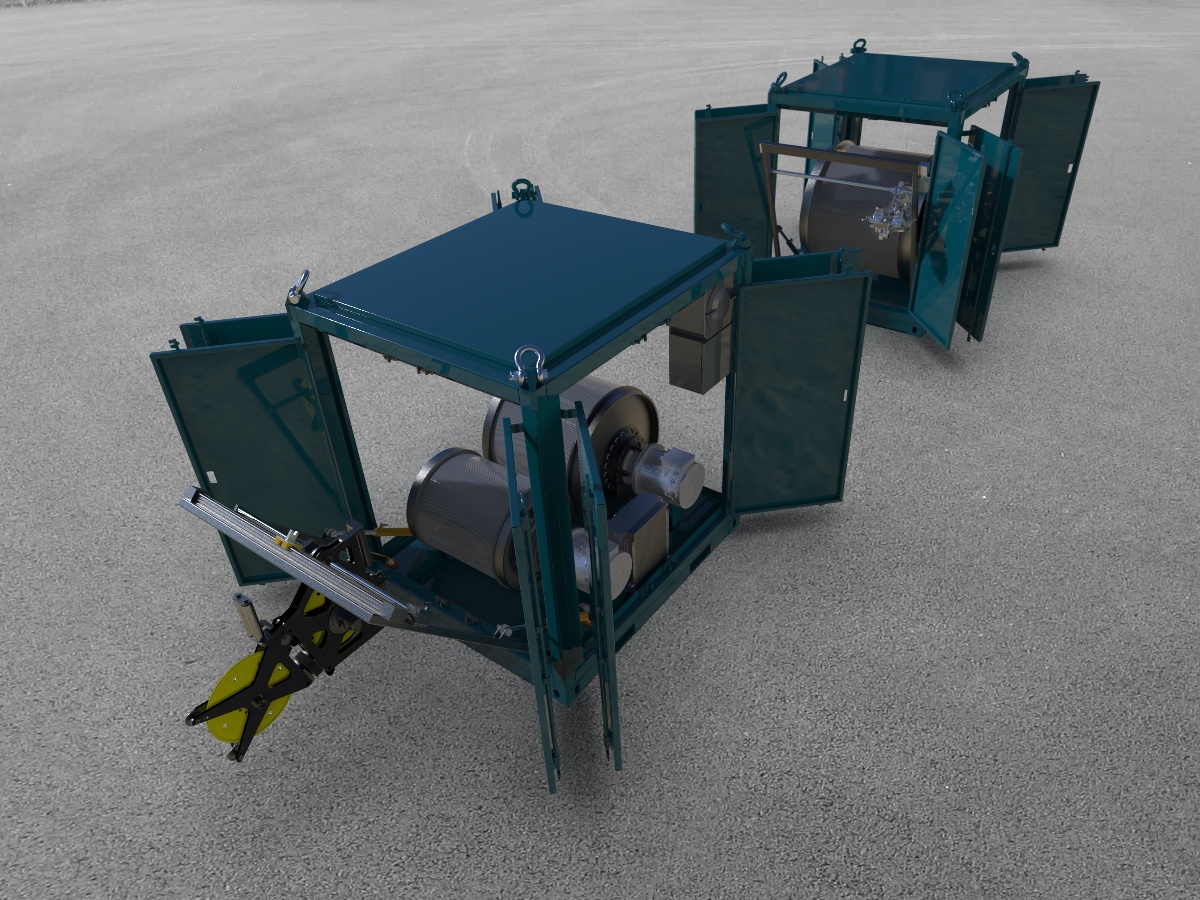

iWinch Wireline Unit

Electric and automated wireline units for cased hole and open hole operations

The iWinch wireline technology is based around an efficient mechanical design, the latest in electrical motor drive technology, married with advanced automation and integration with digital eco-systems.

The iWinch can be configured as single or dual drum units. A set of drums covers slick to braided, mono to multiconductor e-line cables. An electrical level wind places the cable accurately on the drum using advanced spooling algorithms.

The iWinch can be packaged for open hole or cased hole operations, with single or dual drums mounted in containers or custom-designed housings.

iWinch is a flexible workhorse in the most demanding applications

- Drums driven by permanent-magnet motors via heavy-duty gearboxes

- All electric design - no hydraulics

- Accurate creep speed to extreme accelerations

- Single or dual drum versions

- Choice of drums for slickline, braided or E-line covers all industry-standard cable sizes

- Optional hybrid drive (energy saving batteries) drastically reduces fuel consumption

- Performance-adapted to cased hole, open hole, RLWI, heavy-duty work

On the journey to autonomous operations, iWinch is the perfect companion

- Highly automated native auto functions assisting the operator in and out of the well

- Tightly connected with AdvisorX, enabling pre-defined run planning and execution, taking into account best practices, wellbore conditions and reactions to events

- Can integrated and use downhole sensors to control the surface iWinch where applicable

- Can synchronize the surface iWinch with downhole tractors

- Can be interfaced with third-party Well Control Systems

- Can be interfaced with pumping systems for synchronized pump-down operations

The iWinch is designed as a vital part of our Intelligent Conveyance™ technology, forming an integral part of completely autonomous wireline intervention systems.

iWinch may be operated from multiple locations, providing operational and organizational flexibility

- From a Wireline Operator Cabin, seated in an XOS Operator Station.

- From a desk-based XOS Operator Station located in an “ice-box” or Platform office.

- Integrated with the rig’s Drilling Control System, operated from the Driller’s Chair.

- From a wireless rigging panel.

- Remotely from the XOS Remote System, perhaps located in an onshore operation center.

By Intelligent Conveyance, running complete or sections of a job from AdvisorX applications.

Made for offshore operations, fully conform to NORSOK requirements

The iWinch meets and exceeds all NORSOK capacity and performance requirements. Compact and lightweight, it fits North Sea constricted platform spaces, is easily mobilized and rigged up and made ready for operation.

An International version is available where NORSOK standards are not required.

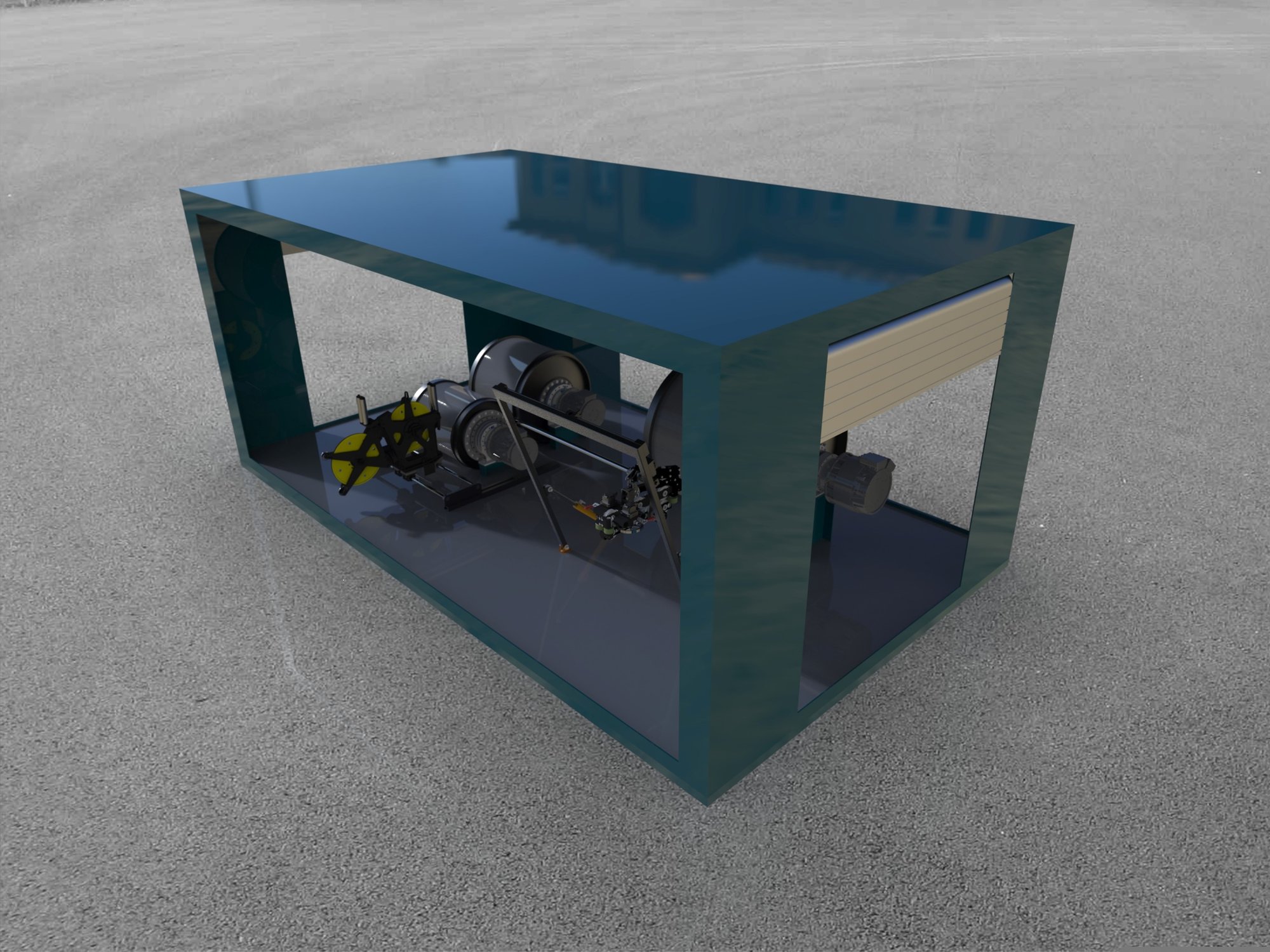

Permanent Wireline System

Creates a permanent infrastructure that accelerates Integrated Operations, enables automation while reducing logistics and unproductive rig time

Permanent Wireline Systems completely changes traditional ways of doing wireline operations on mobile offshore drilling unit.

Instead of a constant mobilization of containers and crews, Permanent Wireline let service companies and / or rig owners offer “wireline on demand” in a collaborative and cost-effective manner.

With a Permanently Wireline System:

- Large reduction in cost of mobilization.

- Rigging time (and cost) strongly reduced.

- Opportunity for more flexible manning, greatly reducing rig site crews.

- Non-productive waiting time almost eliminated.

- A foundation for remote controlled, automated and autonomous wireline operations.

What is the difference between traditional wireline and Permanent Wireline Systems?

- Wireline winch skids are permanently installed in a sheltered housing on board the rig.

- Capacity aligned for all open hole / cased hole wireline operations.

- No wireline containers to mobilize leading to reduced emissions.

- New drums (if required) installed with a dedicated, safe drum change system.

- Everything stays - ready to operate.

- Less crew to mobilize.

- The wireline system is part of the rig’s infrastructure - always ready to be operated.

- Improved collaboration between drilling rig, service company and energy company.

- Wireline can be operated from rig office, Drillers Cabin, remotely, by Intelligent Conveyance™.

Resources

Want to learn more? Check Out

- Wireline Products Pricing Models

- Download Documentation

- Contact Stimline to discuss your opportunities

Pricing

We acknowledge that every company needs individual solutions.

Therefore, we tailor our wireline solutions to the client need and objectives. We collaborate to find the best possible solution and corresponding pricing for the project.

Want to get an indicative proposal or quote for your project?

Documentation

Gain more insight into wireline automation

iWinch Wireline System

Read about how the iWinch Wireline System is all electric automated high performance wireline winch is simplifying wireline operations by use of automation and trusted mechanical components.

Jean-Philippe Huchon

COO and Vice President Sales

Christoffer Sørensen

Business Development Manager, Norway

/Logo/Stimline%20logo%20-%20black%20and%20blue.png?width=2405&height=625&name=Stimline%20logo%20-%20black%20and%20blue.png)